Cross-section Microscopy Analysis of Interior and Exterior Paints: The Quarter (Block 2, Building 48), Williamsburg, Virginia

Colonial Williamsburg Foundation Library

Research Report Series - 1752

Colonial Williamsburg Foundation

Library

Williamsburg, Virginia

2013

CROSS-SECTION MICROSCOPY ANALYSIS REPORT

The Quarter: Interior and Exterior Paint Samples

Block 2, Building 48

COLONIAL WILLIAMSBURG FOUNDATION

WILLIAMSBURG, VIRGINIA

The Quarter, northeast face [Travers 2012]

The Quarter, northeast face [Travers 2012]

| Structure: | The Quarter, Block 2, Building 48 |

|---|---|

| Requested by: | Edward Chappell, Roberts Director of Architectural and Archaeological Research, Colonial Williamsburg Foundation (CWF) |

| Analyzed by: | Kirsten Travers, Paint Analyst, Department of Architectural and Archaeological Research, CWF |

| Consulted with: | Susan Buck, Conservator and Paint Analyst, Williamsburg, Virginia |

| Date submitted: | November 16, 2012 |

Purpose:

The purpose of this investigation is to use cross-section microscopy techniques to study the number and nature of finishes on the interior and exterior of the Quarter. Sample QT 1 should reveal how the exterior cornice was finished prior to the shed addition. The rest of the samples (QT 2 - QT 6), should shed light on how the overhead framing in the main floor was finished before the addition of the plaster ceiling.

History/Description:

The date of this house is unknown, but E. Chappell believes it dates to the first half of the 19th century, based on its traditional framing. It appears to be the only relatively intact Williamsburg house that had exposed framing overhead on the main floor (E. Chappell, sample memo, September 2012). These surfaces were accessed for sampling from the scuttle in the 20th-century closet in the first-floor southwest bedroom. The exterior cornice was accessed from the present first-floor bathroom, which was undergoing renovation.

Procedures:

Six samples (QT 1 - QT 6), were taken by Kirsten Travers and Edward Chappell on September 19, 2012. A microscalpel was used to remove the samples, which were stored in labeled Ziploc baggies for transport. All samples were given the prefix "QT" and numbered according to the order in which they were collected. All sample locations were documented.

In the laboratory, the uncast samples were examined with low-power magnification (5x-50x), to identify those that contained the most intact evidence for cross-section microscopy. The best candidates were cast in resin cubes and ground and polished to prepare the cross-section surfaces for microscopic examination (see Appendix A. for sample preparation details).

3The samples were digitally photographed in reflected visible and ultraviolet light conditions at 200x magnification. By comparing the resulting photomicrographs, finish generations could be interpreted based on physical characteristics such as color, texture, thickness, presence of dirt layers and extent of surface deterioration. The most informative photomicrographs and their corresponding annotations, as well as comments from the author, are contained in the body of this report.

Results:

This analysis yielded good evidence to suggest how parts of the interior and exterior of the Quarter, a 19th-century house, were originally finished. Fluorochrome staining and polarized light microscopy techniques helped characterize the composition of these coatings.

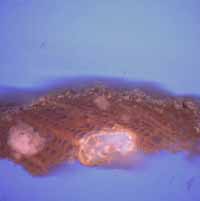

The sample from the exterior cornice (QT 1), contained evidence to suggest it was originally painted white with lead-based oil paints for the first three finish generations. These paints were exposed for a very long period of time and became extremely deteriorated, after which the cornice was limewashed once, before being captured by the rear shed addition. A color match for this first generation white paint is provided on page 11.

The samples from the exposed interior framing (QT 2 - QT 6), suggest that the wood was originally unpainted for a long period of time, as there was a good deal of dirt on its surface. It was then coated five times with unpigmented limewashes, each having a layer of dirt on their surfaces to suggest they were also exposed for a long period of time.

All results are summarized in the conclusion on page 21.

OLD REAR CORNICE SOFFIT (CAPTURED BY REAR SHED)

Summary of results:

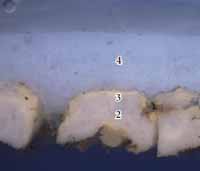

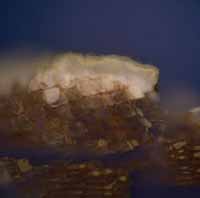

One sample was collected from the cornice soffit (QT 1). Four coating generations were identified.

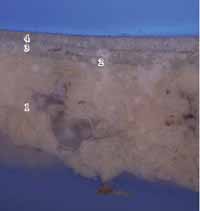

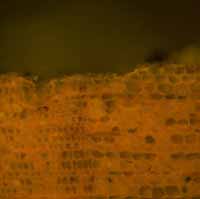

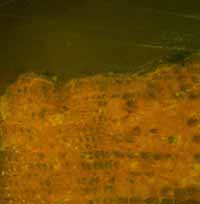

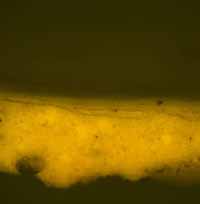

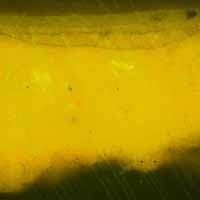

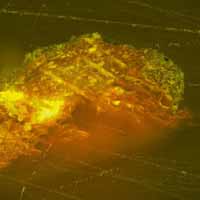

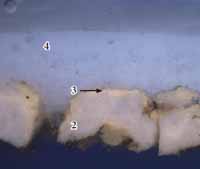

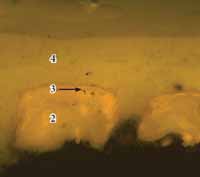

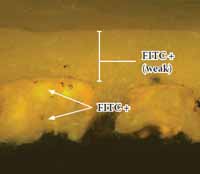

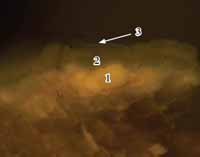

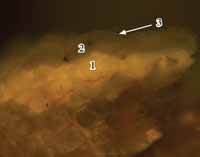

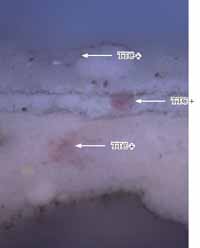

Generations 1 - 3 appear to be lead white oilbound paints, based on their opaque, white appearance in visible light and dim to peach-colored autofluorescence in UV light (confirmed via PLM). These paints appear to have been applied within a relatively short period of time, as no dirt or grime separates them. in fact, in visible light they almost appear to be a single paint layer, but in UV light each has a distinct autofluorescence to suggest they are indeed individual generations. The surface of generation three is extremely worn, dirty, and disrupted, suggesting a very long period of exposure.

Pigment identification was carried out on the first three generations (which could not be separated), and primarily lead white pigments were identified, with a small amount of chalk which could be contamination from later limewashes.

Fluorochrome staining determined that generations 1-3 contain both oil and protein components, although the reaction for oils in the first generations was very weak, possibly due to deterioration and leaching of the binding media.

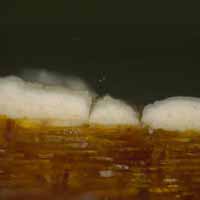

Generation four is an unpigmented (white) limewash, identified via its grayish, translucent quality in visible light and it bluish autofluorescence. The limewash was applied over the very deteriorated oil paints, as it is observed to flow through the cracks in generation three. Fluorochrome staining suggests this limewash contains both oil and proteinaceous components. This is the current surface.

Sample QT 1: old rear cornice soffit of main roof, captured by roof of rear (south) shed

BINDING MEDIA ANALYSIS

TTC for carbohydrates

QT 1c, UV light, 200x. Before TTC stain

QT 1c, UV light, 200x. Before TTC stain

QT 1c, UV light, 200x. TTC reaction

QT 1c, UV light, 200x. TTC reaction

QT 1b, UV light, 200x. Before TTC stain

QT 1b, UV light, 200x. Before TTC stain

QT 1b, UV light, 200x. TTC reaction

QT 1b, UV light, 200x. TTC reaction

Sample QT 1 was stained with TTC to tag carbohydrates in the sample. No true reactions (a dark reddish-brown color) were observed.

FITC for proteins

QT 1b, B-2A filter, 200x. Before FITC stain

QT 1b, B-2A filter, 200x. Before FITC stain

QT 1c, B-2A filter, 200x. FITC reaction

QT 1c, B-2A filter, 200x. FITC reaction

QT 1c, B-2A filter, 200x. Before FITC stain

QT 1c, B-2A filter, 200x. Before FITC stain

QT 1b, B-2A filter, 200x. FITC reaction

QT 1b, B-2A filter, 200x. FITC reaction

Sample QT 1 was stained with FITC to tag proteins in the sample. Moderate to strong reactions (a yellow-green fluorescence) were observed in generations 1-3. A weak reaction was observed in generation four.

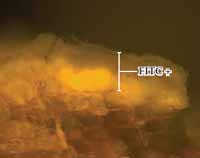

DCF for lipids (oils)

QT 1c, B-2A filter, 200x. Before DCF stain

QT 1c, B-2A filter, 200x. Before DCF stain

QT 1c, B-2A filter, 200x. DCF reaction

QT 1c, B-2A filter, 200x. DCF reaction

QT 1b, B-2A filter, 200x. Before DCF stain

QT 1b, B-2A filter, 200x. Before DCF stain

QT 1b, B-2A filter, 200x. DCF reaction

QT 1b, B-2A filter, 200x. DCF reaction

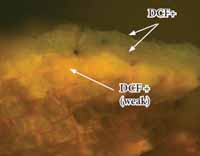

Sample QT 1 was stained with DCF to tag lipids (oils) in the sample. Moderate to strong reactions (a yellow-green fluorescence) were observed in generations 2-4. The weak reaction in generation one could result from the severe deterioration of the binding media.

PIGMENT IDENTIFICATION

Generations 1-3: white paint

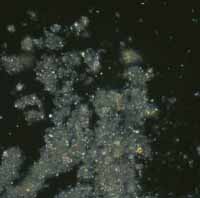

Dispersed pigments from sample QT 1, generations 1-3. Plane polarized light, 1000x

Dispersed pigments from sample QT 1, generations 1-3. Plane polarized light, 1000x

Dispersed pigments from sample QT 1, generations 1-3. Cross polarized light, 1000x

Dispersed pigments from sample QT 1, generations 1-3. Cross polarized light, 1000x

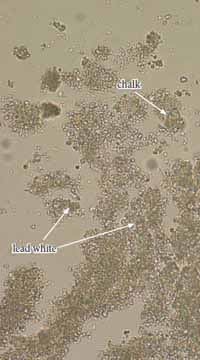

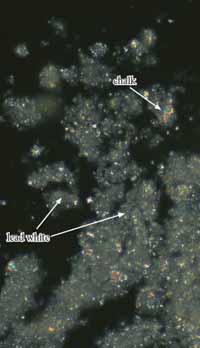

Generations 1 - 3 could not be isolated and were collected as a group. These paints appear to contain primarily lead white pigment (2PbCO3‧Pb(OH)2), visible as small, rounded particles with high relief that are colorless to greenish in transmitted plane polarized light and have a bright birefringence in cross polarized light.

Some chalk particles were also visible (CaCO3), which appear as larger, flat plates with sharp edges and an undulose birefringence. These particles could represent chalk fillers or extenders added to the lead white paint, but are most likely contaminants from the later limewash layers.

COLOR MEASUREMENT

Generations 1: white paint

Despite taking numerous measurements, consistent values for the first generation white paint could not be obtained with the Minolta Chroma Meter colorimeter/microscope. This was most likely due to the extreme deterioration and disruption of this paint. Instead, the closest commercial color match was determined by eye using a stereomicroscope at 30x magnification with a color corrected light source. The closest commercial color match was determined to be Benjamin Moore OC-32 "Tapestry Beige".

| CIE L*a*b* values | L* | a* | b* |

|---|---|---|---|

| 84.17 | -1.58 | +9.70 | |

| Munsell values | hue | value | chroma |

| 5.8Y | 8.3 | 1.3 |

However, pigment identification determined that only lead white, and possibly some chalk, was present in this paint. Therefore, the darker tan color of the above match most likely represents an aged lead white oil paint and does not reflect its original color. Therefore, a commercial match is provided below that was obtained from a sample of hand-ground paint made with lead white pigments in cold-pressed linseed oil (prepared by K. Travers in May 2012. Samples stored in the laboratory of S. Buck).

| CIE L*a*b* values | L* | a* | b* |

|---|---|---|---|

| 93.02 | -1.08 | +5.56 | |

| Munsell values | hue | value | chroma |

| 6.8Y | 9.5 | 0.7 |

UNDERSIDE of ATTIC FLOORING and CEILING JOISTS

Summary of results:

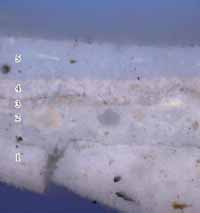

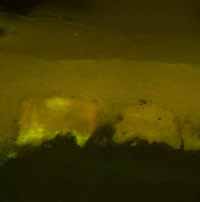

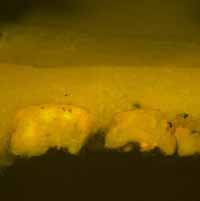

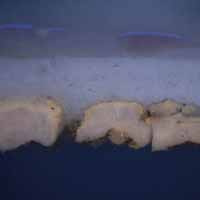

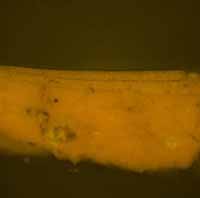

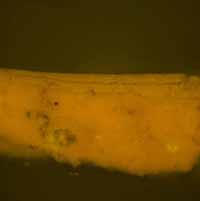

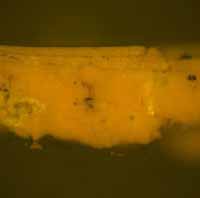

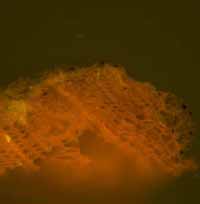

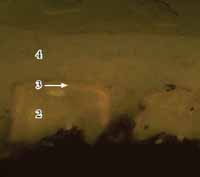

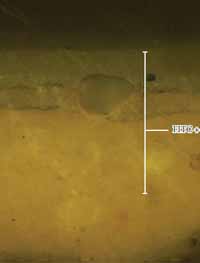

Five samples were collected from the underside of the attic flooring and ceiling joists (QT 2 - QT 6), which would have been originally exposed. All of the samples had similar finish histories, suggesting that all of these surfaces were finished at the same time.

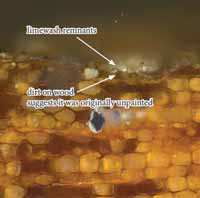

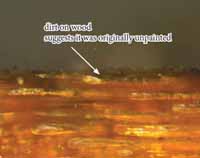

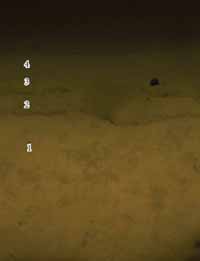

In every sample there is a thick layer of dirt and grime on the surface of the wood, suggesting that the framing was originally unpainted, and exposed for a long period of time.

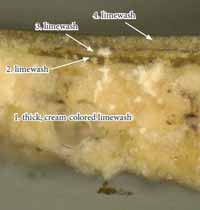

Generation one is a thick cream-colored limewash, which often contained trapped particles of dirt and wood fibers, suggesting the substrate was already deteriorated when this limewash was applied. The layer of dirt and grime on the surface of this limewash suggests it was exposed for a long period of time.

Generations 2 - 5 are unpigmented (white) limewashes that are usually separated by dirt layers to suggest they were exposed for long periods of time before being repainted. Generation five is not present in all samples.

Sample QT 2 was stained with fluorochromes to characterize the binding media, which determined that all limewashes contained carbohydrates (TTC+), proteins (FITC+), and oils (DCF). This suggests that organic additives, such as gums and/or starches, animal glues and/or caseins, and oils were added to improve the working properties and durability of these finishes.

Sample QT 2: Underside of attic flooring, outer (south) pine floorboard just in from rear plate, 3" in from rear edge of board and 2' from outer (west) wall

BINDING MEDIA ANALYSIS

TTC for carbohydrates

QT 2b, UV light, 200x. Before TTC stain

QT 2b, UV light, 200x. Before TTC stain

QT 2b, UV light, 200x. TTC reaction

QT 2b, UV light, 200x. TTC reaction

QT 2a, UV light, 200x. Before TTC stain

QT 2a, UV light, 200x. Before TTC stain

QT 2a, UV light, 200x. TTC reaction

QT 2a, UV light, 200x. TTC reaction

Sample QT 2 was stained with TTC to tag carbohydrates in the stratigraphy. Weak to moderate reactions (a dark red-brown color) were observed in all generations.

FITC for proteins

QT 2b, B-2A filter, 200x. Before FITC stain

QT 2b, B-2A filter, 200x. Before FITC stain

QT 2b, B-2A filter, 200x. FITC reaction

QT 2b, B-2A filter, 200x. FITC reaction

QT 2a, B-2A filter, 200x. Before FITC stain

QT 2a, B-2A filter, 200x. Before FITC stain

QT 2a, B-2A filter, 200x. FITC reaction

QT 2a, B-2A filter, 200x. FITC reaction

Sample QT 2 was stained with FITC to tag proteins in the stratigraphy. Positive reactions (a yellow-green fluorescence) were observed in all generations.

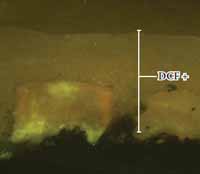

DCF for lipids (oils)

QT 2b, B-2A filter, 200x. Before DCF stain

QT 2b, B-2A filter, 200x. Before DCF stain

QT 2b, B-2A filter, 200x. DCF reaction

QT 2b, B-2A filter, 200x. DCF reaction

QT 2a, B-2A filter, 200x. Before DCF stain

QT 2a, B-2A filter, 200x. Before DCF stain

QT 2a, B-2A filter, 200x. DCF reaction

QT 2a, B-2A filter, 200x. DCF reaction

Sample QT 2 was stained with DCF to tag lipids (oils) in the stratigraphy. Strong positive reactions (a yellow-green fluorescence) were observed in all generations.

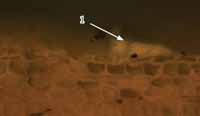

Sample QT 3: Underside of attic flooring, second floor board in from rear plate, 2" in from longitudinal joint and about 2' from the outer (west) wall

Sample QT 4: Ceiling joist, east side, second from the right (west) end of the building, 3" above lower edge of the joist above the rear wall plate

Sample QT 5: Ceiling joist, third from right (west) end, right (west) side, 4" below top, 11" in front of plate

Sample QT 6: Ceiling joist, third from right (west) end, bottom of joist, 11" in from plate and against right edge of joist

In cross-section, the limewashes in sample QT 6 have a darker appearance than the limewashes in samples QT 2 - QT 5. The uncast sample was examined and the same finishes appear to be present (judging by color, thickness, consistency), but some areas do have a more brown-color by comparison. The reason for this difference is unclear.

Conclusions:

Old Rear Cornice Soffit:

The soffit of the old rear exterior cornice was first painted three times with lead white-based oilbound paints. These paints were heavily worn and soiled, suggesting a very long period of exposure. Generation four was an unpigmented limewash that was applied when the white oil paints were already very deteriorated, as it flows into cracks in the preceding generations. The cornice was then 'captured' by the rear shed addition.

Overhead Finishes:

The underside of the attic flooring and the ceiling joists visible from the first floor were originally unpainted, as there is a layer of dirt on top of the wood in all five of the samples collected, suggesting it was uncoated for a relatively long period of time. The first coating is a thick, cream-colored limewash, followed by four additional limewash coatings. Almost all of these coatings are worn and dirty, suggesting long periods of exposure. Fluorochrome staining suggests that all of these limewashes contained organic additives to improve their durability. This would need to be confirmed with an instrumental technique such as Fourier-transform infrared spectroscopy (FTIR) or gas chromatography-mass spectrometry (GC-MS).

Appendix A: Procedures

Sample Preparation:

The samples were cast in mini-cubes of Extec Polyester Clear Resin (methyl methacrylate monomer), polymerized with the recommended amount of methyl ethyl ketone peroxide catalyst. The resin was allowed to cure for 24 hours under ambient light. After cure, the individual cubes were removed from the casting tray and sanded down using a rotary sander with grits ranging from 200 - 600 to expose the cross-section surface. The samples were then dry polished with silica-embedded Micro-mesh Inc. cloths with grits ranging from 1500 to 12,000, lending the final cross-section surface a glassy-smooth finish.

Microscopy and Documentation:

The cross-section samples were examined using a Nikon Eclipse 80i microscope equipped with an EXFO X-cite 120 fluorescence illumination system fiberoptic halogen light source. Samples were examined and photographed under visible and ultraviolet light conditions (excitation 330-380 nm, barrier filter 420nm), at 40 to 400x magnifications. Digital images were captured using a Spot Flex digital camera with Spot Advance (version 4.6) software. All images were recorded as 12.6 MB tiff files and stored on a hard drive in a folder titled "The Quarter" on Susan Buck's laboratory computer. A separate set of images are stored on the CWF digital database, accompanied by a pdf of this report.

Information Provided by Visible and Ultraviolet Light Microscopy:

When examining paint cross-sections under reflected visible and ultraviolet light conditions, a number of physical characteristics can be observed to assist with the interpretation of a paint stratigraphy. These include the number and color of layers applied to a substrate, the thickness or surface texture of layers, and pigment particle size and distribution within the paint film. Relative time periods for coatings can sometimes be assigned at this stage: for instance, pre-industrial-era paints were hand ground, lending them a coarse, uneven surface texture with large pigment particles that vary in size and shape. By contrast, more "modern", industrially-prepared paints have smoother, even surfaces and machine-ground pigment particles of a consistent size and shape. Furthermore, the presence of cracks, dirt layers, or biological growth between layers can indicate presentation surfaces and/or coatings that were left exposed for an extended period of time.

Under UV light conditions, the presence and type of autofluorescence colors can distinguish sealants, clear coatings, and binding media, from darker dirt or paint layers within the stratigraphy. For instance, shellacs exhibit a distinct orange-colored autofluorescence, while natural resins (such as dammar and mastic), typically fluoresce a bright white color. Oil media tends to quench autofluorescence, while most modern, synthetic paint formulations (such as latex) exhibit no fluorescence at all. Some pigments, such as verdigris, madder, and zinc white, have distinct fluorescence characteristics, as well. UV light microscopy is critical to help distinguish otherwise identical layers often found in architectural samples- such as successive varnishes, or multiple layers of unpigmented (white) limewash.

Binding Media Analysis using Fluorochrome stains:

Fluorochrome stains adapted from the biological sciences were used to characterize the paint binding media (oils, proteins, carbohydrates), in layers within the cross-section sample. The following stains were used in this analysis:

2,7 Dichlorofluorescein (DCF): 0.02% w/v in ethanol. Fluorescent labeling reagent for lipids, particularly drying oils. One drop of stain was applied to the surface of the sample, blotted immediately, and cover-slipped with mineral spirits. The reaction was observed with the B2A filter cube (EX 450-490nm, BA 520nm). This stain exhibits a yellow-green fluorescence where lipids are present.

Triphenyl tetrazolium chloride (TTC): 1.0% w/v in ethanol. Labeling reagent for carbohydrates (gums, starches, cellulosic thickeners). One drop of stain was applied to the surface of the sample, blotted dry, and allowed to sit for approximately 45 seconds before cover-slipping, (must be allowed to react with atmospheric moisture for reaction to move forward). The reaction is observed under reflected UV light conditions (EX 330-380nm, BA 420nm). A dark red-brown color is seen where carbohydrates are present.

Fluorescein isothiocyanate (FITC): 0.02% w/v in anhydrous acetone. Fluorescent labeling reagent for proteins. One drop of stain was applied to the surface of the sample, blotted immediately, and cover-slipped with mineral spirits. The reaction was observed using the B-2A filter cube (EX 450-490nm, BA 520nm). A positive reaction is a bright yellow-green fluorescence.

Pigment Identification with Polarized Light Microscopy:

To collect a pigment sample for polarized light microscopy (PLM), a surgical scalpel was used to collect a small scraping from a clean, representative area of paint. The blade was then pressed and pulled across a clean glass microscope slide, dispersing the pigment particles across the surface. The pigments were then permanently embedded under a cover slip using Cargille Meltmount (refractive index 1.66). The embedded pigments were then examined in cross and plane-polarized transmitted light with the Nikon Eclipse 80i microscope at 1000x magnification (using an oil immersion objective). The observed morphologies (size, shape, agglomeration, cleavage patterns), and optical properties (including color, refractive index, extinction), were compared to reference standards as well as literature sources before making final determinations.

Color measurement and matching:

Color measurements were taken using the Minolta Chroma Meter CR-241 colorimeter/ microscope in Susan Buck's paint analysis laboratory. Equipped with an internal 360-degree pulsed xenon arc lamp, this instrument is capable of obtaining accurate color measurements in any one of five different tristimulus color measurement systems from areas as small as 0.3mm. For the purposes of this project, color values in CIE L*a*b* colorspace and the Munsell color system were obtained.

The CIE L*a*b* color space system (developed in 1976 by the Commission International de l'Eclairage, and now an internationally accepted industry-standard color measuring system) uses three numerical values, known as "tristimulus" values, to measure color: L* is the lightness variable, representing dark to light on a scale of 0-100, while a* and b* are chromaticity coordinates, a* representing red to green on scale from -50 to +50, and b*representing blue to yellow on a scale from -50 to +50. These three coordinates are used to plot the location of a color in the CIE L*a*b* colorspace. These resulting values can be used to quantify color differences (Δ E), between two samples. To obtain this value, the following calculation is used:

ΔE = (ΔL*)½ + (Δa*)½ + (Δb*)½A ΔE value ≤ 3 cannot be perceived by the human eye (Wolbers 2008). Therefore, between any two samples, ΔE values at or below this range are considered acceptable matches.

Ideally, color measurements should be collected from a clean, unweathered sample area. If necessary, a scalpel is used to scrape an area clean before color matching. Due to inherent color variations in paints (especially in hand ground, pre-industrial coatings), multiple readings are taken and averaged together to establish the final CIE L*a*b* values.

Due to the deterioration, soiling, and fragmentary nature of some early paints, color readings cannot always be obtained with the Chroma Meter. In these instances, paints are matched by eye to Munsell standard color swatches and commercial paint chips, using a stereomicroscope at 30x magnification with a color corrected light source. Commercial systems consulted include Benjamin Moore, Sherwin Williams, Pittsburgh Paints, and the Colonial Williamsburg Color Collection.

Appendix B. Sample Memorandum

Sent: Wednesday, September 19, 2012

To: Kirsten Travers

Cc: Dani Jaworski

Subject: Exterior and Interior Paint Samples, The Quarter — Block 2, Building 48

This is a list of locations from which you and I took samples at the Quarter this afternoon. The first should reveal some about how the exterior of the buildings was whitewashed and/or painted before addition of the rear shed. The other five should provide solid evidence for overhead finish prior to installation of a plaster ceiling. The date of the house is unknown, but it appears to be sufficiently early to be traditionally framed, so perhaps it dates from the first half of the 19th century. Its brick chimney previously provided a fireplace toward the east, so either the present structure replaced one to the east or once there were rooms east and west of the chimney. The former seems most likely.

The paint samples are important because this appears to be the most modest preindustrial house surviving in Williamsburg. It may be the only relatively intact one that had exposed framing overhead on the main floor. There are beaded and painted joists above plastered ceilings in the west wing of the Coke-Garrett House, but these appear to have been recycled from an earlier building.

- 1.You and I took samples from the bottom of the old rear cornice soffit of the main roof, captured by the roof of the rear (south) shed. The soffit appears to be a relatively poor grade of pine, with a sizable open knot. I cannot see the nails, but I assume the soffit is cut-nailed and 19th-century. A bed molding appears to have been removed long ago, leaving the inner part of the soffit unpainted. To the unaided eyes, the soffit seems to have whitewash and no oil paint. It is difficult to reach above 20th-century wall framing and metal plaster lath, but we took the samples from a location about 3" in from the south (outer) edge and 2" in (west) of the exterior (east) wall.

- 2.The scuttle in the 20th-century closet opening from the first-floor bedroom (southwest room) gives better access to the underside of the attic flooring. Sample 2 came from the outer (south) pine floorboard just in from the rear plate, 3" in from the rear edge of the board, and about 2' from the outer (west) wall.

- 3.Sample 3 is from the second floor board in from the plate, 2" in from the longitudinal joint and about 2' from the outer (west) wall.

- 4.The scuttle also gave me access to the left (east) side of an early ceiling joist in the main block, apparently the second from the right (west) end of the building. This seems to be a pit or straight sawn, not hewn or planed surface, with what to the eye looks like whitewash, possibly with white paint. The sample was taken from 3" above the lower edge of the joist just above the rear wall plate, which was never painted.

- 5.5. The next joist, apparently third from the right (west) end, appears to have sawn side and lower surfaces. Sample 5 came from the right (west) side, 4" below the top, 11" in front of the plate. There appears to be a ¾" unpainted ghost on the side of the joist at the plate, as though finish sheathing or clapboards covered the plate but not the joists and upper flooring.

- 6.Sample 6 came from the bottom of the same joist, 11" in from the plate and against the right edge of the joist.

It would be useful to see more of the house frame in the future.